Discover the Best Plastic Injection Molds for Sale

The Importance of Plastic Injection Molds

In the world of manufacturing and metal fabrication, plastic injection molds play a pivotal role. They are essential for creating parts that are not only durable but also intricately detailed. As industries continue to evolve, the need for high-quality molds has never been greater. This article will delve into the essential aspects of plastic injection molds, their benefits, and why purchasing quality molds from manufacturers like DeepMould.net can significantly enhance your operations.

What Are Plastic Injection Molds?

Plastic injection molds are tooling used to shape molten plastic into a specified design. The process involves injecting heated plastic into a mold cavity, where it cools and solidifies into the final product. This method is widely used in various industries, including automotive, consumer goods, and electronics.

Advantages of Using Plastic Injection Molds

Investing in the right molds can greatly improve production efficiency. Here are some advantages of using plastic injection molds:

- High Precision: Ensures parts are manufactured to exact specifications.

- Efficiency: Allows for mass production, reducing per-unit costs.

- Material Versatility: Compatible with a range of plastics, enabling multiple applications.

- Complex Designs: Capable of producing intricate designs that would be difficult with other methods.

- Reduced Waste: The process is clean, minimizing material waste.

Why Choose DeepMould.net for Your Plastic Injection Molds?

When searching for plastic injection molds for sale, it's crucial to partner with a reliable supplier. Here’s why DeepMould.net stands out:

- Quality: We pride ourselves on delivering only the highest quality molds that meet rigorous industry standards.

- Customization: Our team works closely with clients to design molds tailored to their unique needs.

- Expertise: With years of experience in metal fabrication, our experts ensure optimal design and production techniques.

- Comprehensive Support: From the initial concept to production, we provide full support to our clients.

- Competitive Pricing: We offer affordable options without compromising on quality.

Understanding the Plastic Injection Mold Manufacturing Process

To appreciate the quality of plastic injection molds for sale, it helps to understand the manufacturing process:

1. Design Stage

The mold design phase involves creating detailed CAD drawings that specify dimensions, material choices, and other critical aspects. This stage is vital for ensuring the mold meets required specifications.

2. Material Selection

Choosing the right materials for both the mold and the injected plastic is crucial. High-grade steel or aluminum is commonly used for molds to ensure durability and heat resistance.

3. Machining

Using CNC machines, manufacturers precisely cut and shape the mold components according to the design specifications. This stage requires high precision to ensure a perfect fit.

4. Assembly

After machining, the mold components are assembled. This includes fitting all parts together seamlessly to ensure the injection process runs smoothly.

5. Testing

Before the molds are put into production, they undergo rigorous testing to ensure they function correctly and produce high-quality parts.

6. Production

Finally, once the mold has been tested and approved, it is ready for production. This phase involves repeated cycles of injection molding to produce the required quantity of parts.

Applications of Plastic Injection Molds

Plastic injection molds are incredibly versatile and are used in a variety of applications. Here are some common examples:

- Automotive Parts: From dashboards to exterior trims, injection molds are essential in the automotive industry.

- Consumer Electronics: Molds produce the casings for smartphones, laptops, and other devices.

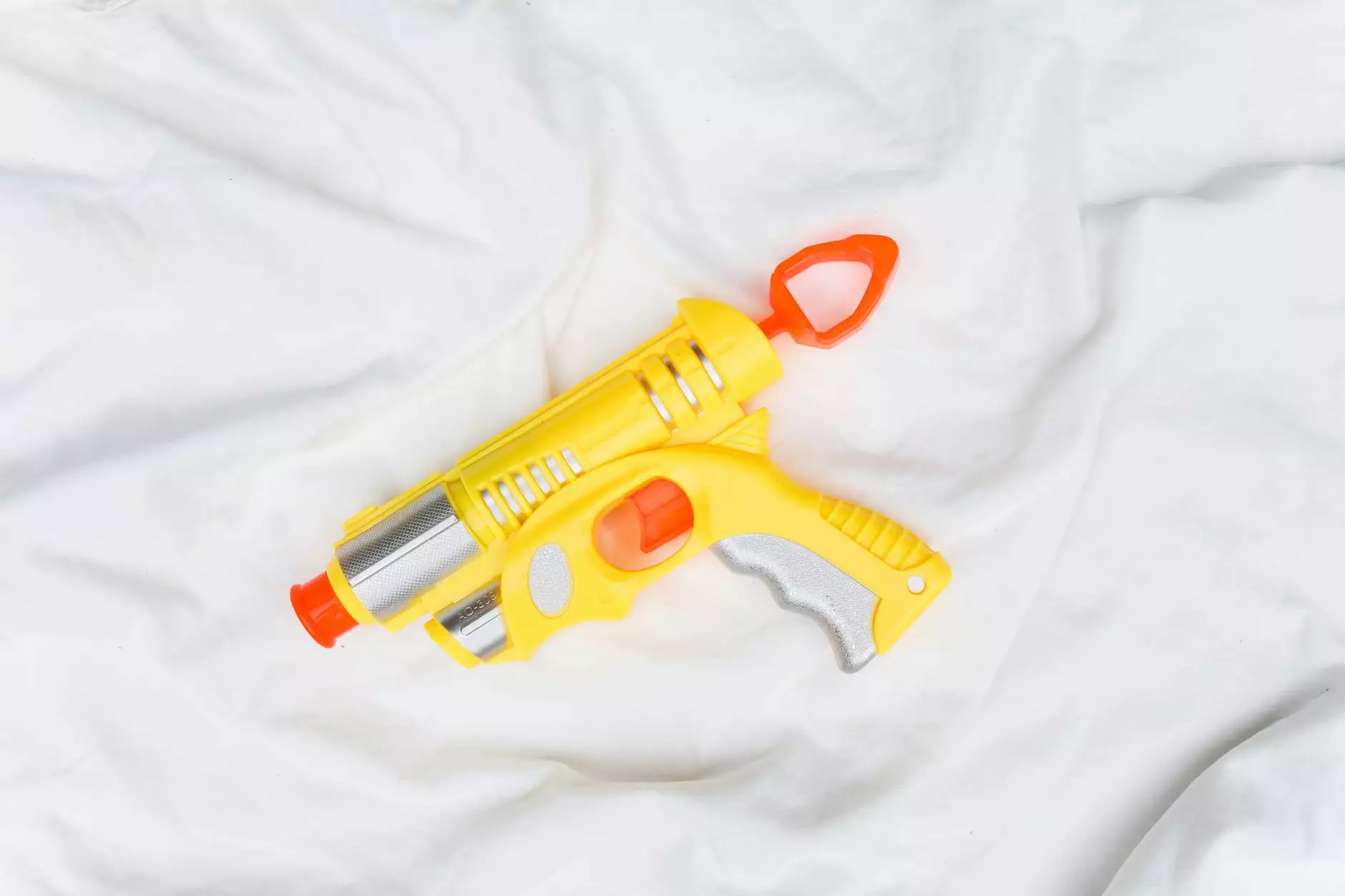

- Household Goods: Many everyday items, including containers, toys, and appliances, are manufactured using this method.

- Medical Devices: Precision molds are critical for producing components in medical instruments and devices.

- Packaging: Plastic injection molding is widely used to create packaging solutions for various products.

Key Factors to Consider When Purchasing Molds

When looking for plastic injection molds for sale, consider the following factors to ensure you make an informed decision:

- Quality Assurance: Verify that the manufacturer adheres to industry standards and provides quality assurance certifications.

- Customization Options: Ensure they offer custom solutions to meet your specific requirements.

- Technical Support: Look for suppliers that offer ongoing support and maintenance for the molds.

- Turnaround Time: Assess lead times for design, manufacturing, and delivery.

- Customer Reviews: Research customer feedback to gauge the reliability and quality of the supplier.

Conclusion

In conclusion, plastic injection molds are an integral part of modern manufacturing processes. For businesses seeking efficiency, precision, and versatility, investing in the right molds is crucial. At DeepMould.net, we provide high-quality plastic injection molds for sale, designed with the utmost attention to detail and industry standards. Our commitment to quality, customization, and customer satisfaction ensures that your business can thrive in a competitive environment.

When you choose us, you are selecting a partner dedicated to your success. Explore our offerings today and take the first step towards enhancing your manufacturing capabilities.

For inquiries, please contact us at DeepMould.net to discover how we can assist you in sourcing the perfect plastic injection molds for your business needs.